Dark vs. Light - 930 Poydras Building Skin Energy Study

On my first day at Eskew+Dumez+Ripple, Mark Ripple asked me a simple question that I assured him could be answered through simulation – something I brought to the table as a new EDR employee. He said that he always wondered how much the dark colored paint of our 930 Poydras multifamily project affected energy use.

So essentially – if dark roofs are bad, are dark exterior walls bad too? Intuition tells me that the effect is small, but we’re a firm that prides ourself on designing with the numbers, so I was determined to plot some curves for Mark. Almost three years later, I finally got around to running the simulations to determine the extent of the effect. Notably, what spurred my motivation was that I’m leaving EDR, a bittersweet but amicable separation due to the arrival of my new son, Theo, and a desire to move closer to family. Nonetheless, I wasn’t about to leave without fulfilling my promise to Mark.

RESULTS

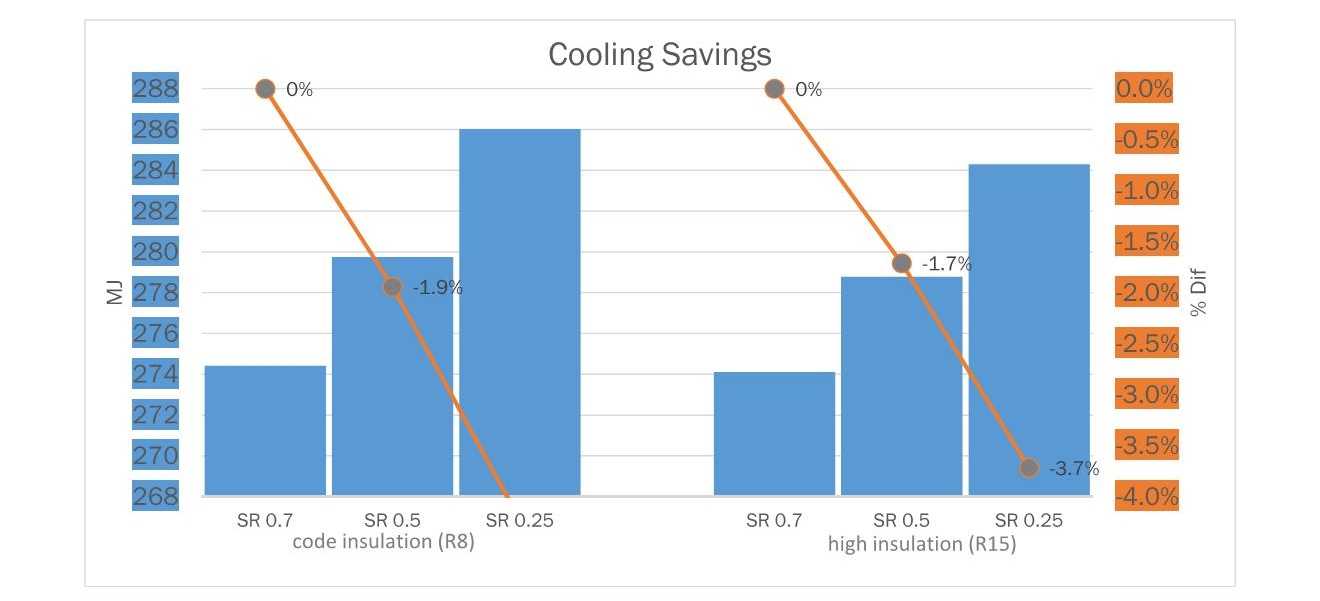

The short answer is from the lightest possible skin to darkest, the spread is about a 1% savings in total energy. Not quite enough to muscle around the aesthetics of the project, but in some cases every % counts. Looking at a code vs. high insulation case doesn’t seem to affect the results much (1% vs. .9%). Interestingly enough, the effect saves about 4% of the cooling energy, but incurs about a 8% penalty in heating. Overall heating and cooling only account for about 25% of the total energy in this climate for this building type, and cooling is a much higher percentage – thus the 1% effect. Given this heating vs. cooling dynamic, looking at energy cost savings might produce a slightly more pronounced effect. Finally, going with the lighter would be better for the heat island effect, but the impact here is not as great as a roof that points towards the sky – but that’s a whole different simulation…..and blog post.

PROCESS

Alright, so, simple process, right? Albeit a simple question, the solar reflectance of materials is a complicated thing to calculate, so I had to fire up OpenStudio and EnergyPlus to fully model the physics. Sefaira, Insight 360 in Revit, and DOE 2.2 just wouldn’t cut it. I hadn’t run these tools in a while, given the workflow I tried to institute at the firm was based on distributing much easier programs across the firm. But, it was an excuse to use OpenStudio’s parametric modeling tool, PAT, which would be helpful to run a variety of different solar reflectance values across a code and high insulation baseline.

Now, I didn’t have a model of 930 Poydras, so I just used the Department of Energy’s Commercial Reference Buildings pre-built EnergyPlus models. They were close enough to determine the effect of skin solar reflectance, and would save me tons of time. Additionally, the latest version of OpenStudio (v 1.14……good heavens, I started on version .4…….I’m so old), has the ability to generate .osm version of the .idf reference files through their “measures” workflow, which was my pathway to parametric design in PAT.

Okay, so after generating the “medium-rise apartment building,” I had to do two things: 1) figure out exactly how to model a targeted surface reflectance and 2) set up the models to be ran parametrically.

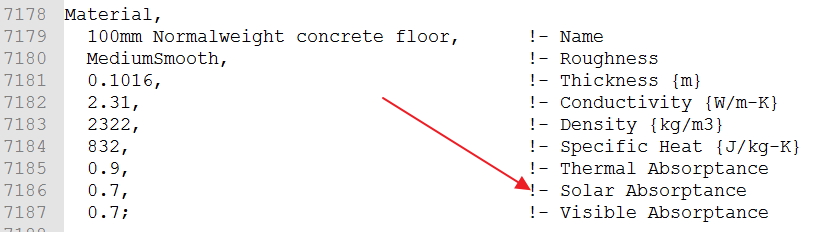

Step 1 – the depth of specification for materials in EnergyPlus is one of its strengths, and you can model anything that you’d ever want to – i.e. density, specific heat, thermal absorption, etc. Most importantly, you can specify something called “Solar Absorptance,” as a number between 0-1.0, the difference being the solar reflectance. Bingo. Next, I found a metal panel manufacturer that actually reported solar reflectance, most just report SRI which is slightly different, and found their colors range from a .25 (dark gray), to .7 (white). I threw in a .5 case for good measure and had my 3 solar reflectance values. For the 2 insulation cases, I just used the code minimum (an effective R8 wall), and the advanced energy design guideline recommendation (an effective R16).

Step 2 – to use a parametric workflow, I had to find OpenStudio “measures” that modified this material parameter. “Measures” are basically pre-packaged scripts that people upload to a database that you can download for free. After generating the initial seed model in OpenStudio with both an insulation and a solar reflectance measure, I could finally open the model in the PAT interface. This allows me to set up multiple runs with different permutations of measures, and then run them on my local machine or using a cloud Amazon account. Here’s what it looks like in PAT in case you’re interested.

PAT doesn’t have a good results reporting interface, so I manually opened up the results files, poured them into excel, and reported the graphs that were included earlier in this post. It’s amazing the workflow it took to answer this question, but it’s a microcosm simulation in general. Workflow is king and you’ve always got to know a variety of programs – not one can answer them all.