Achieving the New Materials Points in LEED v4

The new LEED v4 has a few points related to materials transparency. Here are some notes on the process with the TURCC project.

LEED Materials points deal with calculations or counting up of permanently installed products. What qualifies as a permanently installed product? First the permanency of the product matters. Furniture may be counted, but if it is then ALL furniture must be included in all calculations. A product must be permanently installed, so formwork that ends up being recycled cannot be counted. Since one of the points relies on the number of products that meet certian criteria, where does one product end and another begin? LEED offers the following: Drywall is a single product when it is in its complete form and brought on site. The glue and paper that make up drywall are a single product. A concrete admixture or (in other words) something added to the product on site is a separate product. So the adhesive that keeps a flooring material down or the metal studs that keep the drywall up are separate products. Finally mechanical, electrical or plumbing equipment may be counted if chosen, but unlike furniture, mep items that do not meet the criteria need not be included in calculations.

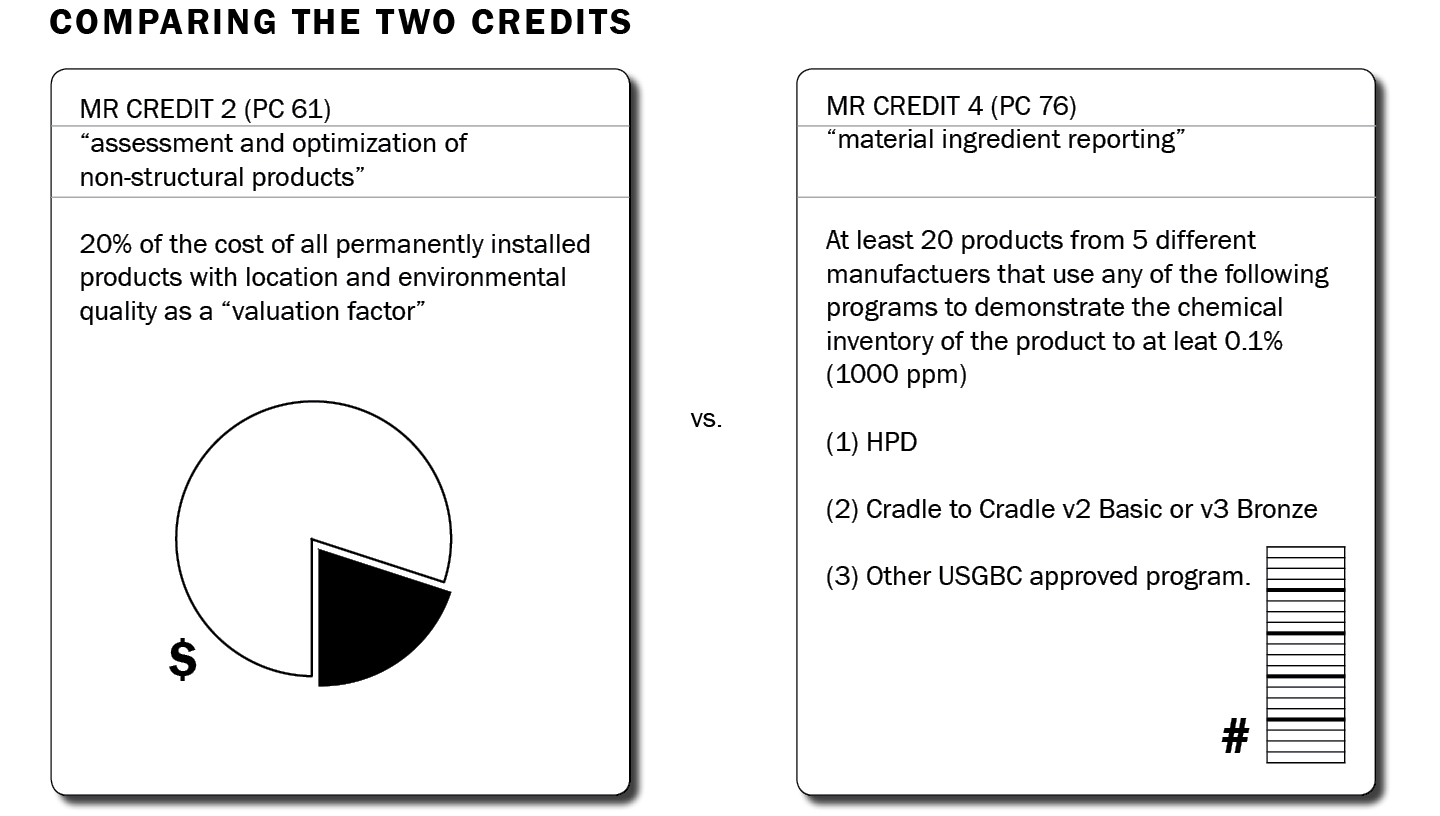

The two new credits are MRc2 and MRc4. Through MRc4, the LEED effort is towards broad market impact in the area of transparency: more participation from more product companies. MRc2 evaluates the magnitude of impact within the individual project. Location and environmental quality are valuation factors in the cost-based calculation, adding greater value to products made within 100 miles of the project site and those with better environmental practices.

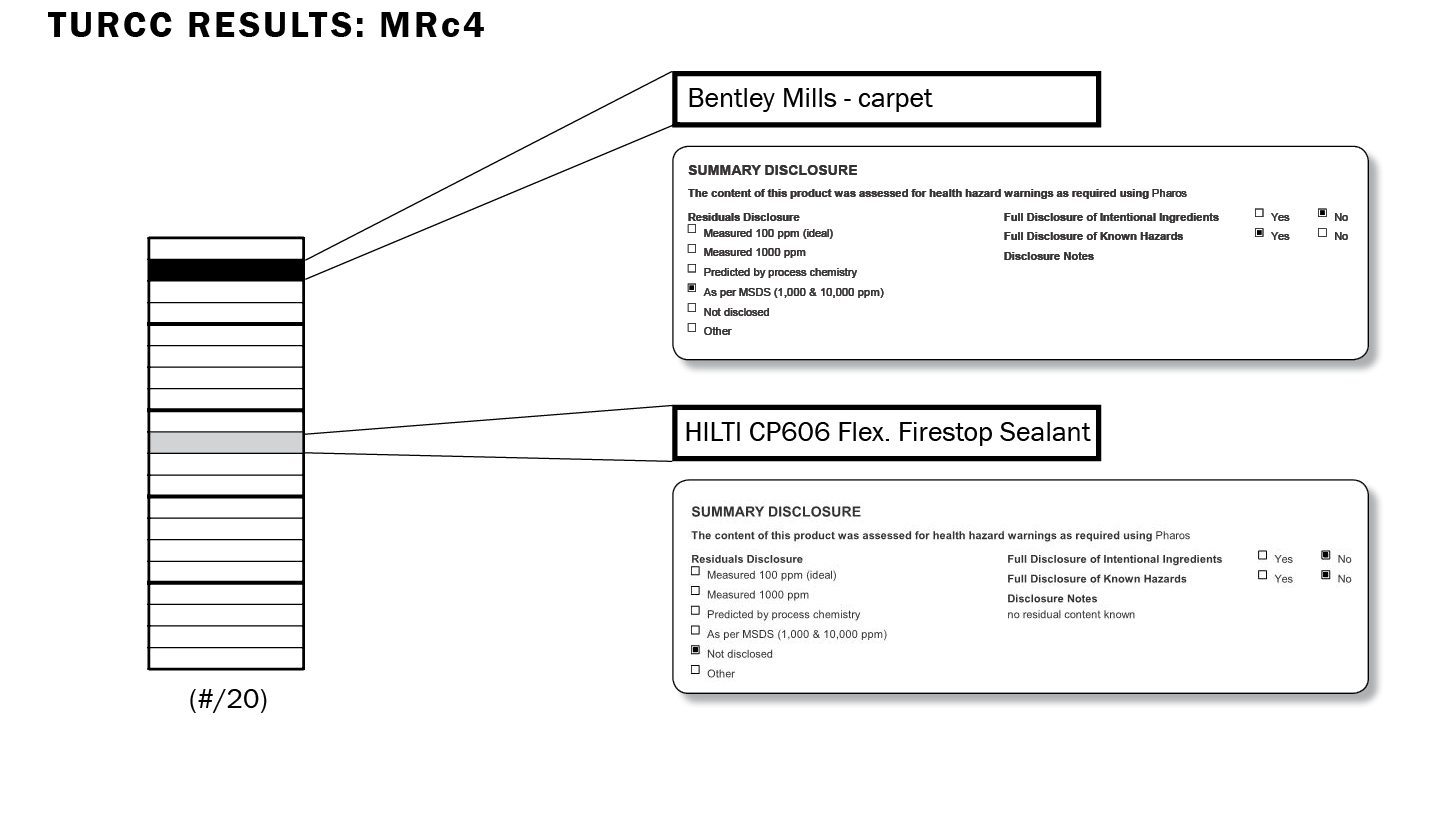

Achieving MRc4 proved quite difficult. Only the Bentley Mills carpet actually met the criteron described by LEED: full disclosure of known hazards and measured to at least 0.1%ppm or 1000ppm. Hilti Flex Firestop Sealant does not meet the criterion, since they do not disclose all known hazards. LEED endeavors to make achievement of these points not based solely on a single method, offering CASRN identification and Cradle to Cradle v3 Bronze certification also as ways to achieve points. The CASRN identification is difficult for a designer to sift through since the information is often presented in an MSDS, without stating whether the 0.1% evaluation has been made.

While many interior finishes companies are taking up the health product declaration and Cradle to Cradle certification as a way to get their products sold, other materials have less incentive to make that investment, so for a project like TURCC that has fewer interior materials, credit 4 achievement was difficult.

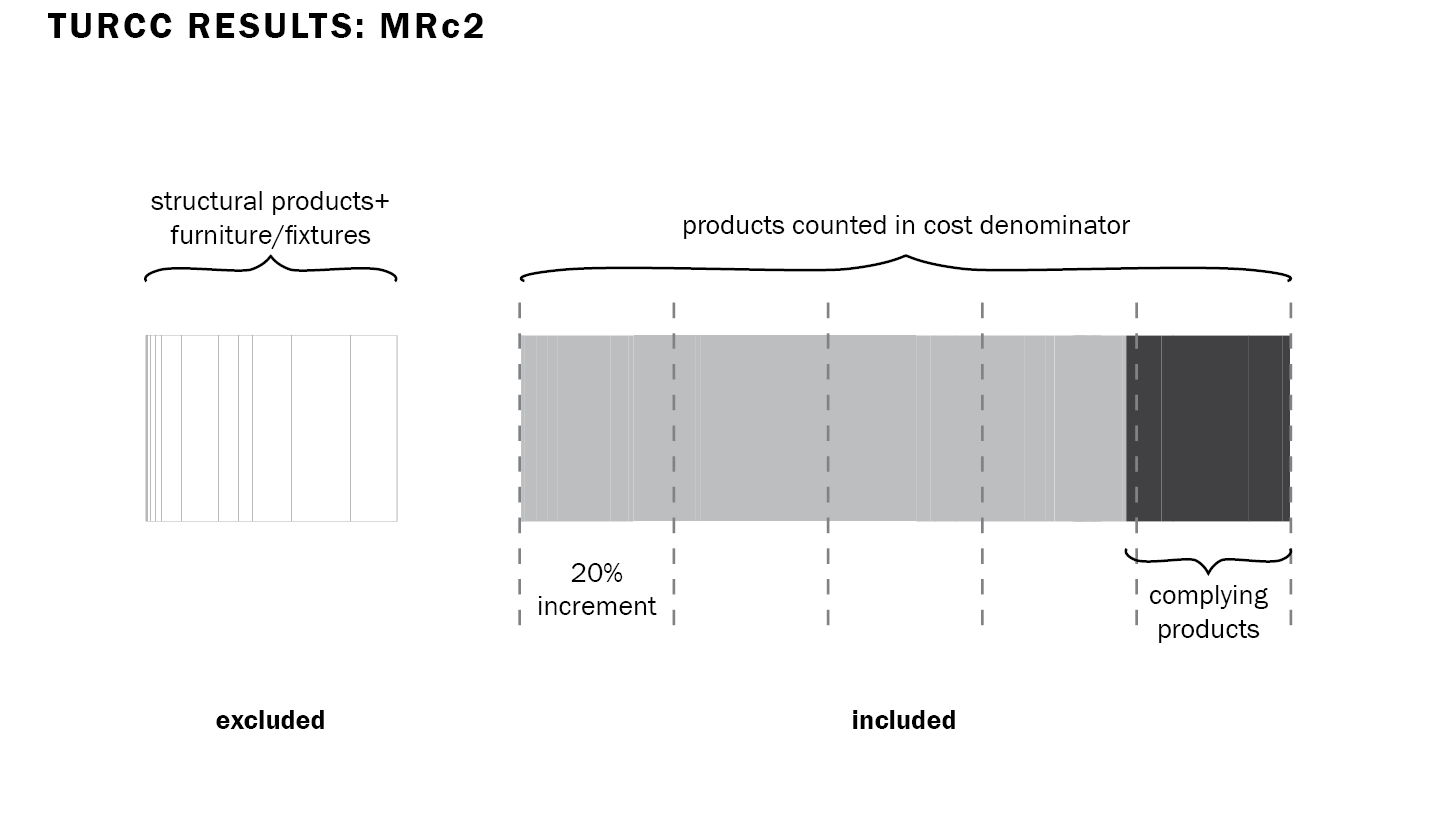

Looks like TURCC can earn Credit 61! It's a cost-based credit that prioritizes the ISO14025 compliant EPD. First, structural products, furniture and fixtures could be excluded. The cost of all remaining products was placed in the denominator and the added up cost of all complying products were placed in the numerator of the calculation. Unfortunately, none of the complying products qualified for a location valuation, but we appear to have just barely reached the 20% threshold.

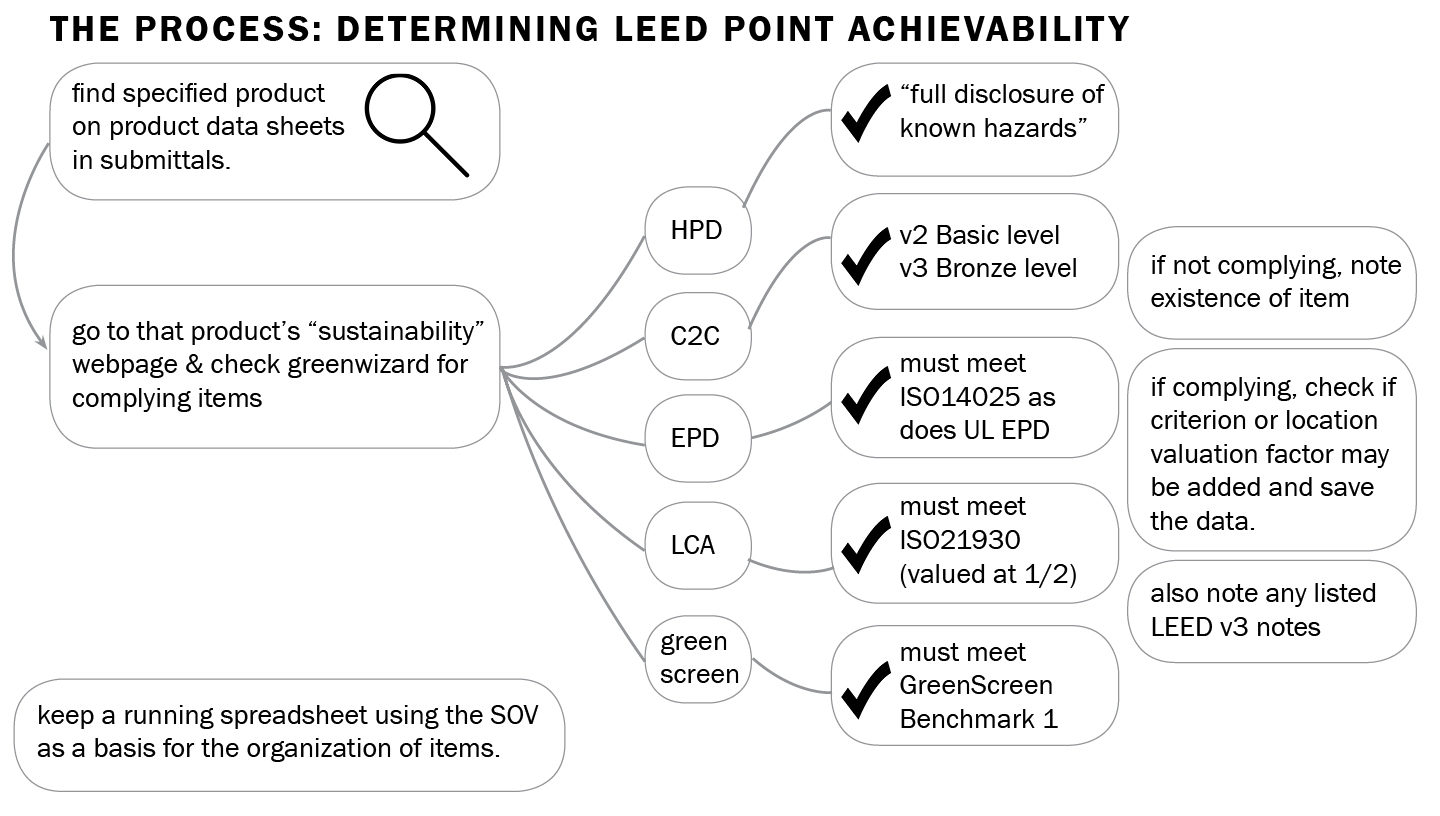

Finally, some process tips in case you are evaluating a project for any of these points:

- Begin with a spreadsheet showing all the SOV items as a basis for the organization of your data collection.

- Keep a column for comments on the product and a column for an alternative product that meets the criteria if possible. As you look through the product data sheets in submittals, once the specified product has been determined seek out information about the product company through their "sustainability" webpage. You can also use Greenwizard through this process, although it's still an incomplete database.

- Seek out HPDs, Cradle to Cradle certifications, Environmental Product Declarations, Life Cycle Assessments and Green Screen items, always checking whether these meet LEED v4 requirements.

The movement to choose materials mindfully continues to grow as a force of change in design.